- #Fusion 360 project to surface how to#

- #Fusion 360 project to surface Patch#

- #Fusion 360 project to surface series#

- #Fusion 360 project to surface free#

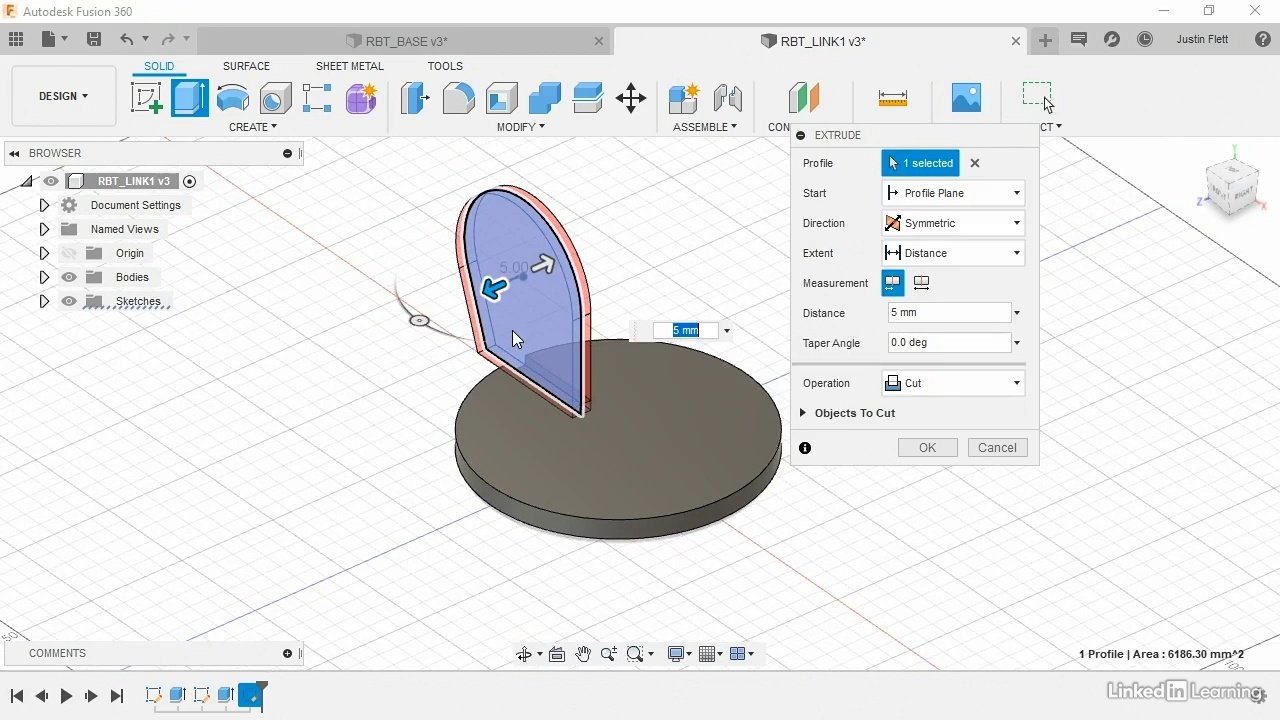

I may want to carve it onto the curved shell, so that it curves around the cylinder. I have a 2D black and white image of this sound wave. I may want this carving to go all the way through the shell (practically making a hole the shape of my pattern) or,I may just want to engrave on part of the shell, but not cut all the way though.

Now, I wish to carve / engrave a pattern on the shell. I was able to create such hollow cylinder using the cylinder and shell tools. For example a hollow cylinder with the bottom closed and the top open. I started by creating a hollow cylinder, with the one end open and the other end closed.

To take you Inventor skills to the next level, why not consider our certified Autodesk training courses.Let me start with a disclaimer: I'm new to 3D design, to design in general and specifically brand new to Fusion 360.

#Fusion 360 project to surface how to#

It’s just about using the correct connection type and understanding how to apply it. This goes to show that Inventor is more than capable of creating high quality G2 surfaces, and as such is a great tool for industrial design of consumer goods. A G2 or smooth connection has the same curvature value for both surfaces at the connection. For example, a flat face with a fillet on it has a fixed radius on the fillet, but the radius of a flat plane is infinite. To understand why we must look at the point of connection, with a tangent joint, the new surface may be tangential, but at the point of connection the radius of the two surfaces are different.

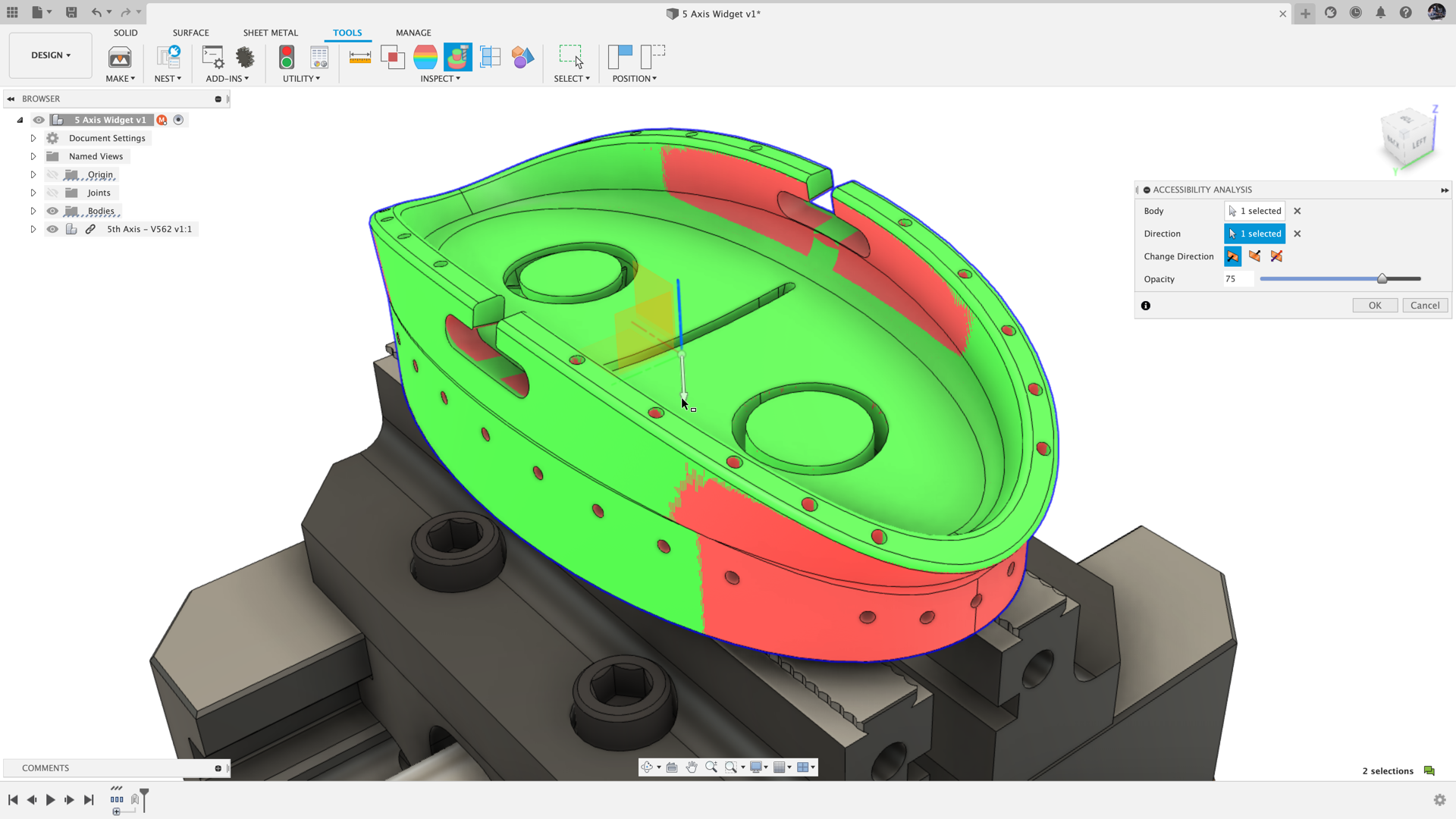

The best connection is the G2 or smooth type ( see image right).

#Fusion 360 project to surface free#

Although superior to a free connection it is still not really good enough for consumer type product design. This connection looks more pleasing, but with polished or shiny surfaces a distinct line can be seen where the point of tangency occurs. So what are the differences in a nut shell between the quality of connection between the two surfaces.Ī free connection has no connection other than the location, so it’s like a sharp corner.Ī tangent connection ( see image left) is getting better and as the name suggests the new surface is at a tangent to the selected. Smooth (G2) – the surface has a G2 continuity to the selected surface. Tangent – the surface is at a tangent to the selected surface. The three options are įree – no condition, the surface is simply attached to the curve/edge. These conditions are very important when creating surfaces.

The real power of this feature is that each curve can have a condition placed on it. This uses a closed loop of either edges or curves to create a surface.

#Fusion 360 project to surface Patch#

Another way to create a surface would be to create a solid and then delete a face to leave an open surface.Īnother method would be to create a patch surface. What this creates is a surface, which depending on the feature type and sketch can be either open or closed. To begin with any of the features can be used to create a surface, simply by selecting the surface option. Inventor can create some very nice quality surface data, with all that is required from the user being an understanding of how to choose from the options.

#Fusion 360 project to surface series#

For the first part of a series on Autodesk Inventor Surface Creation, I will look at the different types of surface connection that are available.

0 kommentar(er)

0 kommentar(er)